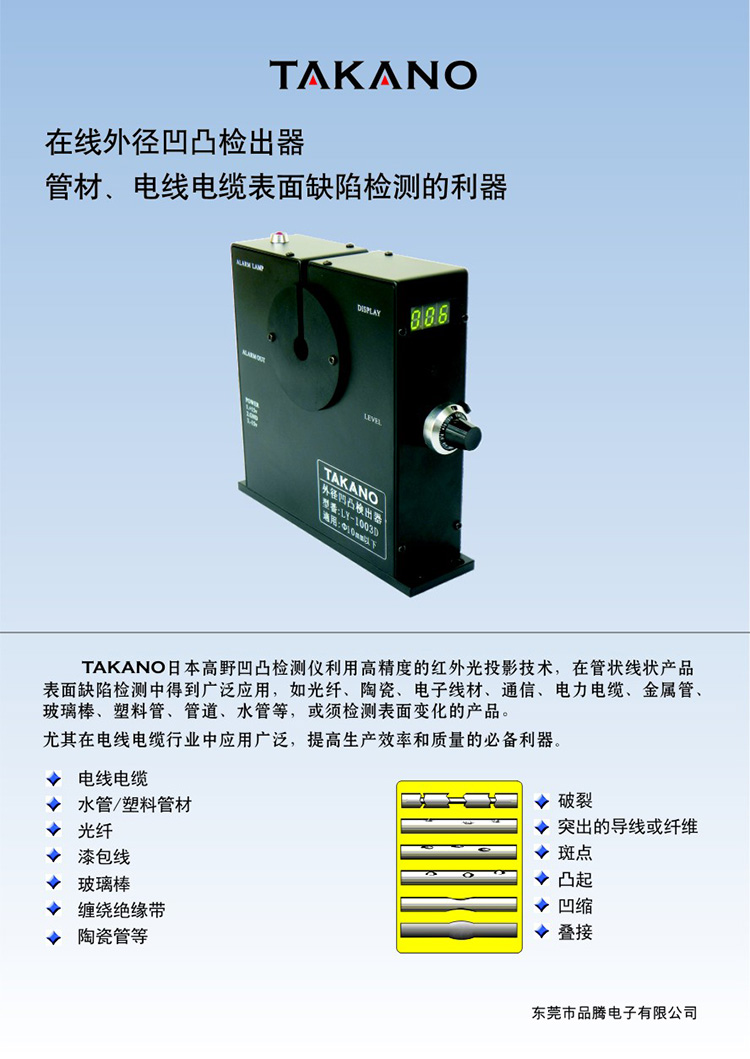

wire cable concave-convex Detector

Japan TAKANO Wire and Cable Bump Detector: The Pioneer of Precision Detection Technology |

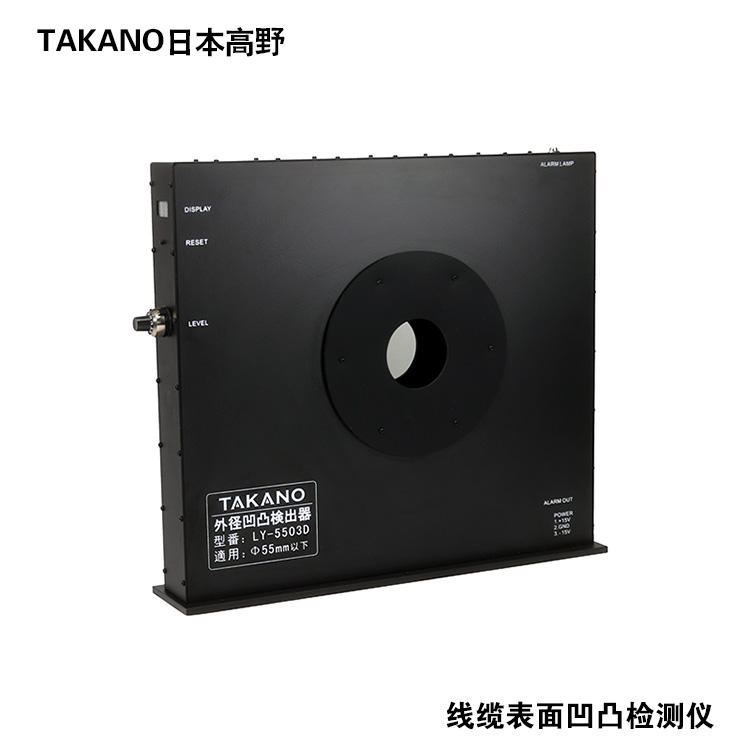

Medium wire counterpart (Measurement object diameter: Φ 0.05 to 55 mm) | ||||||

Model No. | LY-0503D | LY-1003D | LY-2003D | LY-2503D | LY-3503D | LY-5503D |

Direction of detection | 3 directions | 3 directions | 3 directions | 3 directions | 3 directions | 3 directions |

Measurement method | Double slit infrared LED projection type | |||||

Adaptive work outer diameter | φ 0.05 - 10 mm | φ 0.1 - 25 mm | φ 0.2 - 35 mm | φ 0.2 - 55 mm | ||

Unevenness detection range | 0.05 to 10 mm | |||||

Unevenness detection accuracy | Maximum setting within ± 1% | |||||

Slit length | 48 mm | |||||

Slit width | 1 mm | |||||

Linear speed [*1] | 1 m / min to 1500 m / min | |||||

Recorder output | ± 0.1 V / 0.1 mm (for each axis) | |||||

Alarm output | Uneven red LED lit, Relay contact output (AC 250 V 2A resistive load) | |||||

Alarm time [*2] | 0.5 seconds | |||||

Operating temperature | -5 to 50 ° C (without condensation) | |||||

Power supply [*3] | AC 100 V-240V 50/60 Hz | |||||

Power consumption | 10VA | 10VA | 15VA | 20VA | 25VA | 35VA |

Outer dimension | 150 × 142 × 40 [mm] | 150 ×142 × 40 [mm] | 300 × 246 × 40 [mm] | 300 × 246 × 40 [mm] | 300 × 246 × 40 [mm] | 405 × 350 × 60 [mm] |

Weight | 1kg | 1kg | 2kg | 4kg | 4kg | 5kg |

Japan TAKANO Wire and Cable Bump Detector: The Pioneer of Precision Detection Technology

In the rapidly developing modern industry, wire and cable, as the "blood vessels" for power transmission and signal transmission, their quality is directly related to the stability and safety of the entire system. In order to ensure the flawless quality of wire and cable, manufacturers need to rely on advanced detection equipment, and the Japan TAKANO Wire and Cable Bump Detector is undoubtedly a leader in this field.

TAKANO, a brand with a history of 30 years originating from Japan, has won wide acclaim in the global market with its exquisite craftsmanship and outstanding performance. Its wire and cable bump detector, as a star product in the field of quality inspection, has become an indispensable detection tool for many wire and tube production enterprises by virtue of its high-precision infrared optical projection technology.

High Precision, Non-contact Real-time Detection

The TAKANO Wire and Cable Bump Detector adopts advanced double micro-slit, near-infrared light non-contact continuous measurement technology. It can detect various surface defects such as bumps, dents, spots, cracks, and overlaps accurately without damaging the surface of wire and cable. This non-contact detection method not only improves the detection accuracy but also greatly extends the service life of the equipment and reduces maintenance costs.

Wide Range of Application Fields

The application range of this detector is extremely wide, covering various tubular products such as optical fibers, ceramics, electronic wires, communication cables, power cables, metal pipes, glass rods, and plastic pipes. Whether it is fine wires, wire and cable or large pipes, the TAKANO Wire and Cable Bump Detector can complete the detection tasks with its excellent performance. In the wire and cable industry, it has become an essential weapon for improving production efficiency and product quality.

Outstanding Performance and Advantages

1.?Stable Detection Reliability: The TAKANO detector adopts high-precision sensors and advanced algorithms to ensure the stability and reliability of detection results.

2.?Flexible and Convenient Installation: The equipment is compact in design, and the installation process is simple and fast, which can adapt to the needs of various production environments.

3.?Lightweight and Durable: It is made of high-quality aluminum alloy materials, with a lightweight body that is durable and can withstand long-term high-intensity work.

4.?Simple and Intuitive Operation: The user-friendly operation interface and intuitive display screen enable operators to quickly get started and accurately perform detection operations.

5.?Insensitive to External Light: The unique infrared optical projection technology enables the detector to maintain stable detection accuracy performance even in complex light environments.

6.?Alarm Output Interface: When a defect is detected, the equipment will immediately send out an alarm signal and output relevant information, facilitating operators to handle it in a timely manner.

7.?Simple Maintenance: The equipment has a simple structure, and maintenance is convenient and fast, reducing the operating costs of enterprises.

8.?Up to 2000 Scans per Second: The infrared optical projection technology enables the detector to achieve a scanning speed of 2000 times per second, ensuring that no defect is missed.

9.?Line Speed Up to 1500 Meters per Minute: The extremely high detection speed can improve the production efficiency of equipment in various industries.

10.?Unaffected by the Color, Material and Vibration of the Tested Wire: Any color and material of the product can be detected without affecting the accuracy.

Strong Market Competitiveness

With its outstanding performance and wide range of application fields, the TAKANO bump detector has strong competitiveness in the market. Many enterprises choose TAKANO as their quality inspection partner to jointly promote the improvement of product quality and the development of the industry.

In conclusion, the Japan TAKANO bump detector has become a benchmark in the field of modern industrial quality inspection with its high-precision, non-contact detection technology and wide range of application fields. In the future development, TAKANO will continue to adhere to the concepts of innovation and excellence and provide global customers with higher-quality and more efficient

Medium wire counterpart (Measurement object diameter: Φ 0.05 to 55 mm) | ||||||

Model No. | LY-0503D | LY-1003D | LY-2003D | LY-2503D | LY-3503D | LY-5503D |

Direction of detection | 3 directions | 3 directions | 3 directions | 3 directions | 3 directions | 3 directions |

Measurement method | Double slit infrared LED projection type | |||||

Adaptive work outer diameter | φ 0.05 - 10 mm | φ 0.1 - 25 mm | φ 0.2 - 35 mm | φ 0.2 - 55 mm | ||

Unevenness detection range | 0.05 to 10 mm | |||||

Unevenness detection accuracy | Maximum setting within ± 1% | |||||

Slit length | 48 mm | |||||

Slit width | 1 mm | |||||

Linear speed [*1] | 1 m / min to 1500 m / min | |||||

Recorder output | ± 0.1 V / 0.1 mm (for each axis) | |||||

Alarm output | Uneven red LED lit, Relay contact output (AC 250 V 2A resistive load) | |||||

Alarm time [*2] | 0.5 seconds | |||||

Operating temperature | -5 to 50 ° C (without condensation) | |||||

Power supply [*3] | AC 100 V-240V 50/60 Hz | |||||

Power consumption | 10VA | 10VA | 15VA | 20VA | 25VA | 35VA |

Outer dimension | 150 × 142 × 40 [mm] | 150 ×142 × 40 [mm] | 300 × 246 × 40 [mm] | 300 × 246 × 40 [mm] | 300 × 246 × 40 [mm] | 405 × 350 × 60 [mm] |

Weight | 1kg | 1kg | 2kg | 4kg | 4kg | 5kg |

QQ客服

QQ客服